BLS Safety Guide: Asbestos

A guide written by Dr. Antonio Moffa, Dr. Claudia Beccaria and Lucrezia Giorgi of the Unit of Integrated Therapies in Otolaryngology at the University Polyclinic Campus Bio-Medical Foundation in Rome.

The body shop sector is made up of a large number of companies, most of them artisan-type, which have risk factors that may be related to building structures, equipment, machines and installations as well as the products used.

The activity of car repairer includes the maintenance and repair of motor vehicles, including mopeds, agricultural machinery, trailers and carts, used for road transport of persons and goods.

The activity of car repair can be distinguished into:

• mechanics and motoring, which includes work on fuel systems, work on LPG-methane systems, engine overhaul and rectification, work on radiators, replacement of mufflers, and general mechanical overhaul;

• car electricians, which includes repair workshops for electrical and power systems of motor vehicles;

• tyre repair, which consists of repair and replacement of motor vehicle tyres, rebalancing and convergence of tyres;

• bodyshop, which involves repairing the bodywork of industrial vehicles, buses, camping vehicles and the like by means of sheet metal work and painting, replacing or repairing windscreens and windows, rust treatment, etc.

The work of body repairers involves a multitude of risks, including inhalation of fumes, welding gases, grinding or sanding dust, paint aerosols, solvent vapours during the filling and painting of car parts or complete cars, vapours and aromatic hydrocarbons, exposure to solvents when cleaning work tools and airbrushes.

The main occupational diseases of workers in the sector are respiratory diseases and in particular bronchial irritative diseases and bronchial asthma. (see table)

Thus, many products are used in auto body shops that are useful and necessary to carry out the activity, but which can be hazardous to human health and/or safety.

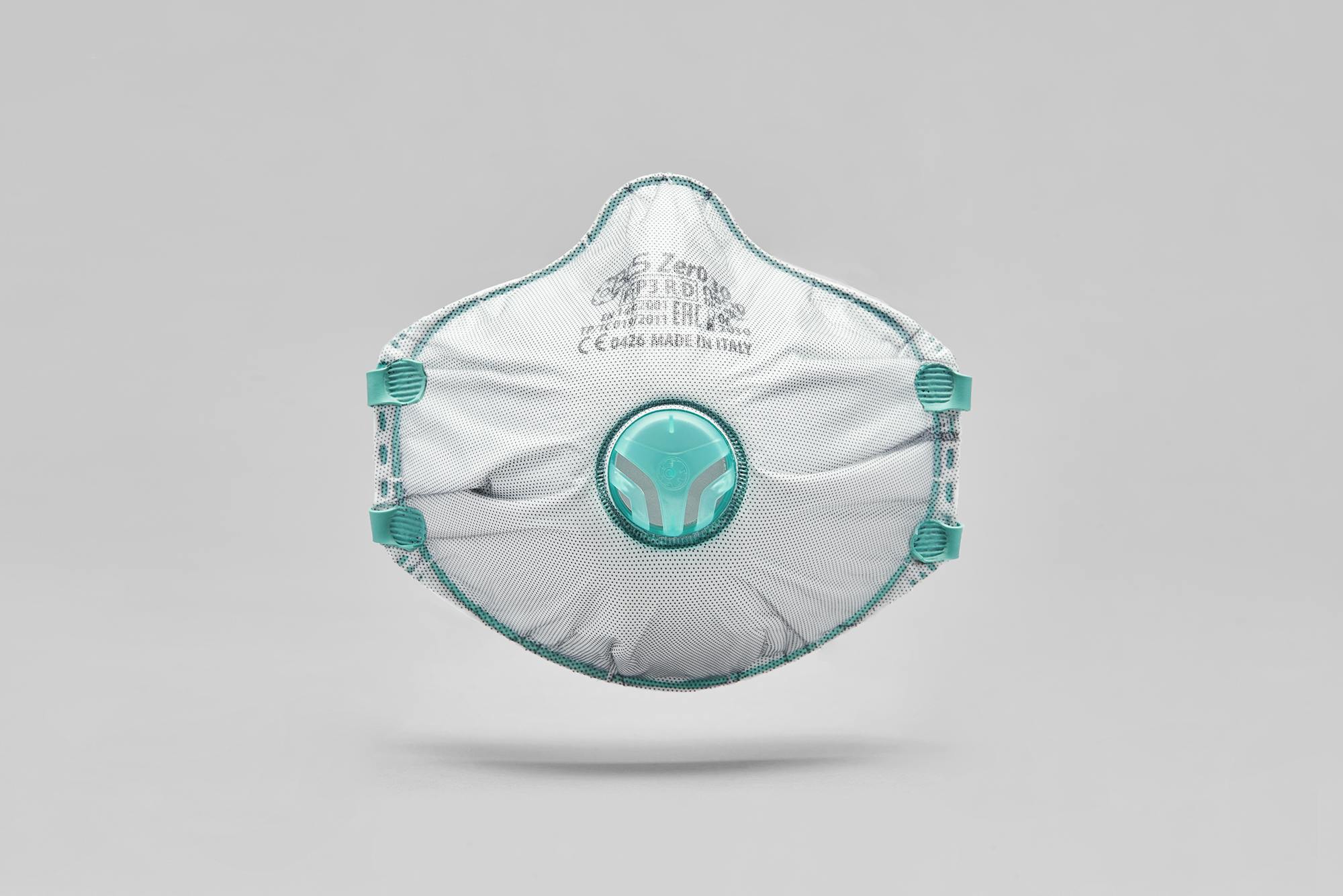

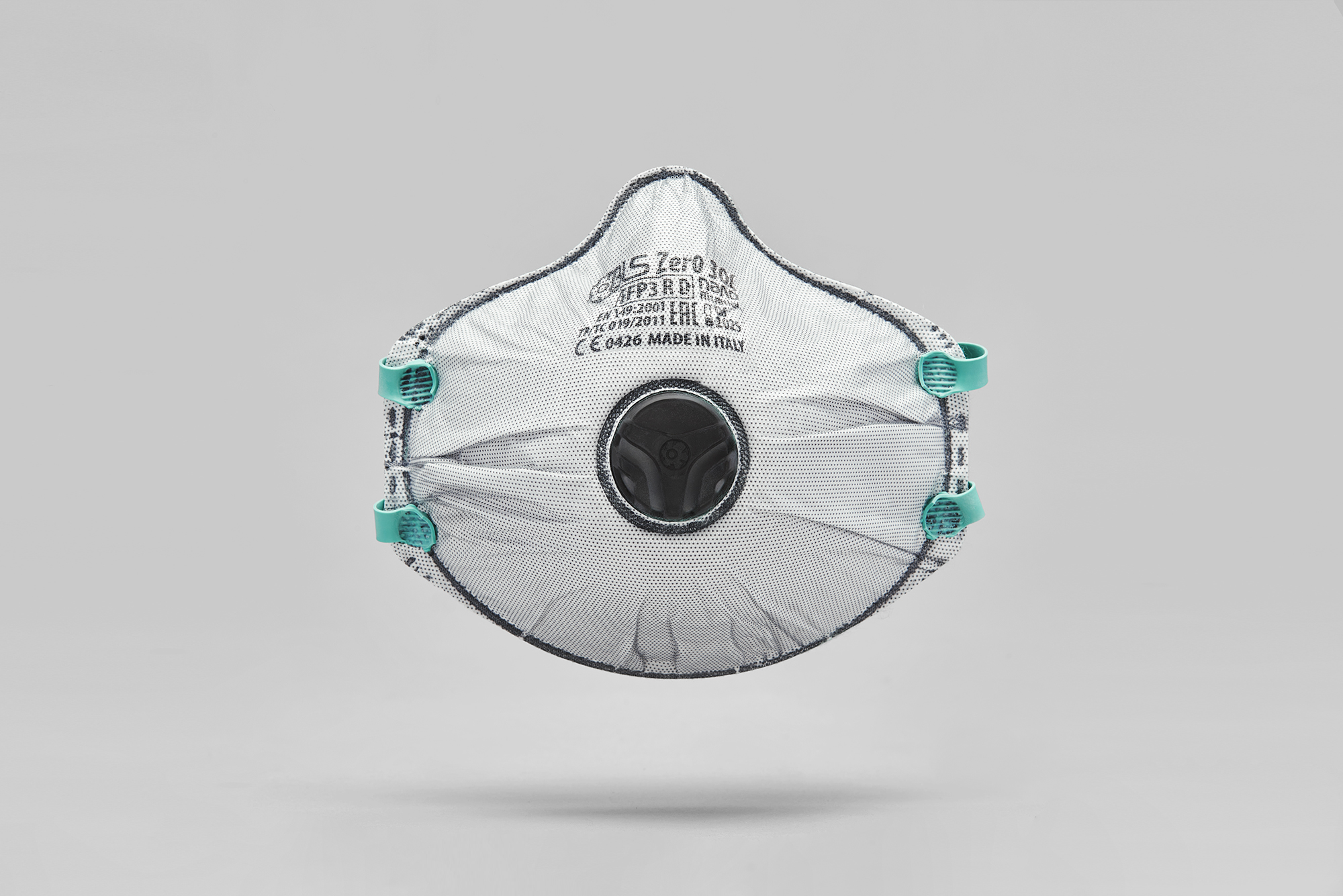

The risk due to the use of hazardous substances is often poorly perceived as many chemicals can be dispersed in the working environment (in the air) and enter the body through different routes (inhalation, swallowing and through the skin) without even being aware of it. The use of personal protective equipment for the respiratory system is therefore necessary for exposure to organic dusts and vapours. In particular, halfmasks with combined dust and vapour filters should be used for painters, and disposable FFP2 or FFP3 filtering masks for plasterers and sanders.